Indutrade acquires UK Gas Technologies Group

UK Gas Technologies Ltd, which comprises Puretech Process Systems Ltd, Medical Gases Ltd and Microgas Systems Ltd, was acquired by Indutrade on 17th September 2020.

One day will all laboratories be built like this?

The innovative high integrity delivery systems we recently designed and delivered for a ground-breaking biomedical facility make flexi lab working and off-site construction a reality. Flexible Laboratories The scale of the gas delivery system which uses over 75,000 metres of copper pipework to supply more than 3000 outlets in the laboratories is impressive in itself […]

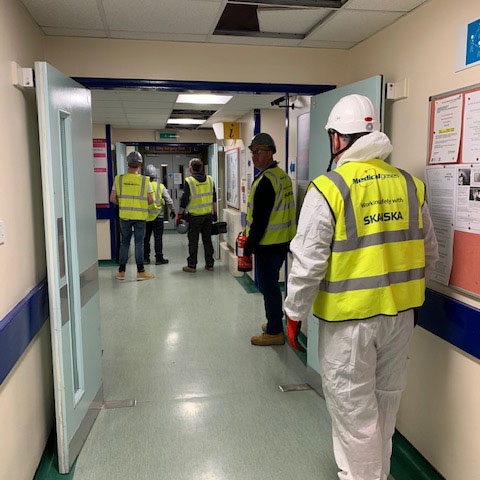

Delivering in record time for coronavirus wards at Epsom University Hospital

CASE STUDY : EPSOM UNIVERSITY HOSPITAL Project: Epsom University Hospitals Covid-19 Wards Client: Interserve / Epsom and St Helier University Hospitals Timing: 25th – 28th March 2020 Value: £1.6M Medical Gases completed a project, including over 1000 meters of pipework, in less than a week to boost oxygen supplies to the coronavirus wards at […]