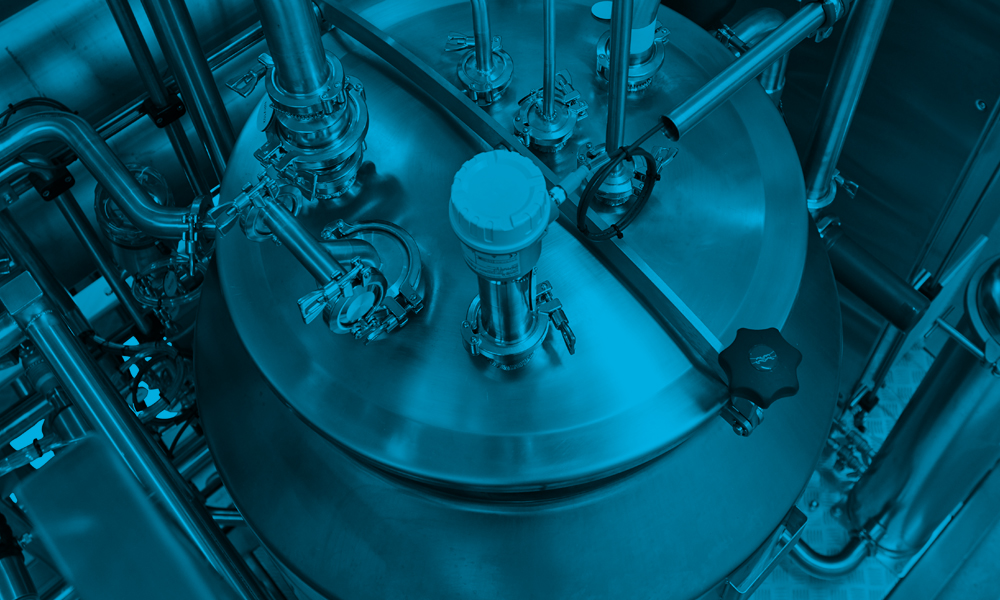

Mixing Vessels

Talk to us

We design, manufacture, and validate custom-built mixing vessels for the Pharmaceutical, Biotechnology, Healthcare, and Life Science industries. Our vessels are engineered to meet the highest standards of hygiene, compliance, and operational performance — supporting your critical processes with precision and reliability.

Designed for Compliance and Performance

All our vessels are designed in-house, tailored to your unique process requirements and fully compliant with:

- cGMP, FDA, and MHRA guidelines

- ASME BPE, GAMP5, and ISPE standards

- Specific User Requirement Specifications (URS)

We provide full 3D modelling and engineering design documentation to support your project from concept to completion.

Standard & Custom Specifications

Our mixing vessels are available in a wide range of sizes, materials, and configurations to suit every stage of production — from R&D to full-scale manufacturing.

Typical Specifications

Specification

Details

Volume Range

10L to 10,000L (larger on request)

Material of Construction

316L Stainless Steel

Surface Finish

≤ 0.51μm Ra electropolished (internal)

Impeller Types

Mixing Speed

Variable speed control (manual or automated)

Heating/Cooling

Temperature Range

-10°C to +150°C

Pressure Rating

Cleanability

Instrumentation

Temperature, pressure, pH, level, conductivity probes

Ports & Connections

Tri-clamp as standard, or custom to suit process

Agitator Drive

Top-mounted, bottom-mounted, or magnetic drive

Control Integration

Standalone or integrated with SCADA/BMS/DCS systems

Manufacturing Excellence

All vessels are manufactured at our UK facility under strict quality control protocols. Our fabrication team works closely with our engineering and validation departments to ensure each unit meets exacting standards.

- Full traceability of materials

- Pressure testing and weld documentation

- FAT/SAT preparation and execution

- Conformance to PED, ASME, and CE marking where applicable

Complete Validation & Documentation

Puretech supports your QA and compliance teams with comprehensive validation packages, including:

- Factory Acceptance Testing (FAT)

- Site Acceptance Testing (SAT)

- Installation & Operational Qualification (IQ/OQ)

- Welding maps and surface finish certificates

- Material and test certificates (EN 10204 3.1)

- 3D As-built drawings and documentation packs

Applications

Our mixing vessels are ideal for a range of applications including:

- Buffer and media preparation

- Vaccine formulation

- Emulsification and suspension

- Bioreactor feed systems

- Aseptic ingredient blending

- Final product formulation

Service & Maintenance

Puretech have nearly 30 years’ experience of servicing and maintaining pharmaceutical, validated water systems.

Our service contracts are tailored to our clients individual needs and the service is expertly provided through our network of experienced and qualified engineers.

We can offer contracts of 1-5 years with the numbers of visits specified by you. All of our contracts as standard receive 24/7 telephone support, recommended spare parts list and a detailed service report to ensure you comply with all regulatory body standards.

Looking for a custom solution?

Our team will work with you to design, build, and validate the exact vessel your process needs.

Please contact us for further information

- Email: sales@puretech.uk.com

- Phone: +44 (0) 1737 378 000

- Website: www.puretech.uk.com