Manufacturing Capabilities

Puretech’s UK-based 40,000 sq/ft manufacturing facility has been purpose-built to support the rising demand for modular system builds, from small-scale skid units to full containerised process systems.

We offer a wide range of in-house capabilities to streamline project delivery, improve build quality and minimise on-site disruption.

Skid-building capabilities

We manufacture process and utility skids for high-purity water systems used across pharmaceutical, life sciences, and specialist manufacturing industries. Each unit is fully built and tested in our facility before delivery, reducing installation time and improving commissioning outcomes.

Modular pipework systems

Puretech engineer and produces modular pipework systems that are delivered to site in pre-assembled sections, dramatically reducing installation time and improving build consistency.

Our solutions feature:

- Factory-built pipe racks and support frames

- High-load-bearing capacity for complex pipework runs

- Adjustable, flexible layouts for tight or constrained spaces

- Seamless incorporation into site facilities and equipment

These modules are built, constructed, and pressure-tested within our factory before being delivered to site – enabling a seamless installation with minimal disturbance to live operations.

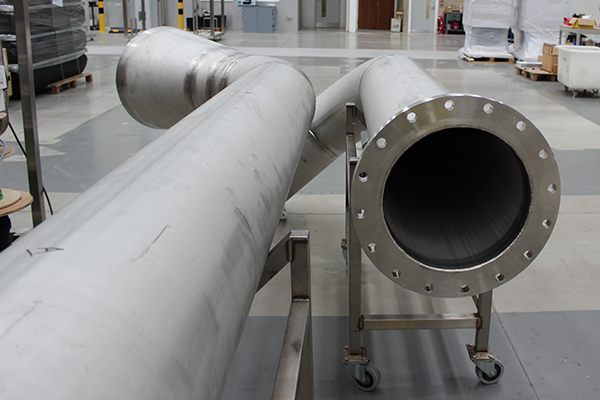

Pipe spool fabrication

We fabricate a wide range of pipe spool pieces in-house, with high-spec welding capabilities across the following sizes:

- Not sure on sizes??

Quench pipe fabrication

We specialise in the production of quench pipework, and we design custom solutions to suit your system pressure and thermal safety requirements.

Modular plant room layouts

We design, fabricate and assemble plant rooms in our factory to reduce the amount of time that we work onsite.

This facilitates better quality control, more rapid commissioning and reduced disruption to your live environment.

Bespoke containerised systems

Puretech designs and delivers turnkey containerised solutions – engineered to meet client specifications.

These plug-and-play units are ideal for rapid deployment and include all necessary utilities, controls, and validated systems.

Testing, inspection and quality assurance

We’ve invested heavily in quality assurance and testing facilities to give our clients confidence and control at every stage of the build process.

Our site includes:

- Wet FAT (Factory Acceptance Testing) Area

- Dry FAT Area

- Dedicated FAT Meeting Rooms

- In-house Calibration Area

- Separate Carbon Steel Fabrication Area (fully isolated from stainless steel)

- Control Panel Build Area

- Gas recycling systems – built and tested in-house

Puretech is a trusted manufacturer of gas recycling systems, built and tested entirely in-house.

We operate 16 dedicated testing bays to ensure performance, reliability, and compliance with strict industry requirements.

Spares & consumables

We maintain an extensive stock of spares and consumables to support ongoing maintenance and reduce client downtime.

Our inventory includes critical-path items for fast deployment during service windows or unplanned maintenance.

Facilities overview

- Factory size: 40,000 sq/ft

- Height clearance: 15m

- External yard: 1,000 sq/m (approx. 10,764 sq/ft)

- 16 individual test bays for gas systems

- Dedicated areas for stainless steel, carbon steel, panel building and calibration

Talk to us

For more information about our solutions why not download our brochures

Let’s Discuss How We Can Work Together!

We would welcome the opportunity to discuss how Puretech can become your trusted partner. We’d love to schedule a meeting to explore potential synergies and discuss how we can support your design projects with our expertise.

Please contact us to schedule a meeting:

- Email: sales@puretech.uk.com

- Phone: +44 (0) 1737 378 000

- Website: www.puretech.uk.com