CASE STUDY : LONGi

LONGi is one of the six major Chinese manufacturers of photovoltaics and a developer of solar projects and the world’s largest manufacturer of mono-crystalline silicon wafers. We have supplied and installed 55 Argon0 units to serve existing and brand new facilities in Malaysia.

Delivering cost and carbon savings to an existing facility

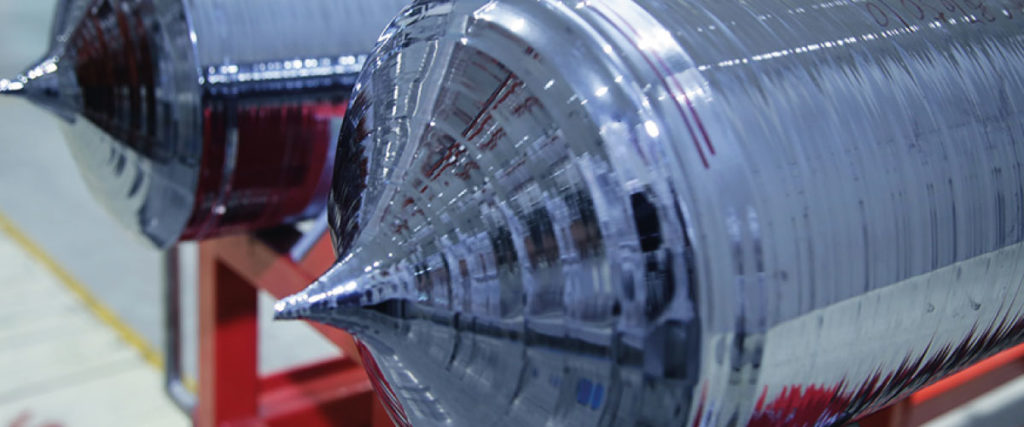

The Argon0 units, which are relatively compact (about the size of a double wardrobe) and simple to install, can serve up to four furnaces at a time in this application. 15 of those supplied have been seamlessly integrated into LONGi Solar’s existing photovoltaic facility in Kuching, Malaysia where they have now been running 24 hours a day for over a year, delivering a return rate of over 94%.

Working with a Chinese-speaking partner in Taiwan to assist with client liaison and the installation, our UK commissioning engineer headed the team to ensure that the commissioning of the units met our standards. Post commissioning, a representative from our partner GR2L attended the site to confirm that all the units were working correctly.

Good working relations and a proactive attitude from those on site contributed positively to the speed and success of the project at Kuching.

Helping LONGi to retain its leadership position

40 Argon0 of the units we have supplied to LONGi have been installed in a brand-new facility for the production of 5GW monocrystalline ingots in Yunnan Lijiang, China. It is our largest installation to date and probably the world’s largest installation for argon recovery. The stand-alone nature of the Argon0 and the fact that it connects to furnaces rather than the factory exhaust stream gives it a clear commercial advantage in simplicity of installation, which was an advantage on this project where we were working around other elements of the installation, and offers the potential for clients to test in situ.

LONGi has expressed a clear intent to concentrate on producing cost effective monocrystalline products* in order to consolidate its leading position in this segment. The Argon0s will contribute to this mission by reducing their demand for argon and will also have a significant impact on the carbon footprint of this huge business.

Creating one of the world’s largest know installations for argon recovery

Supplying 55 Argon0 units in one order is a considerable commitment but the team rose to the challenges in delivering a project of this scale and the units were ready on time and on specification.

Attention to every aspect of our delivery

The Argon0 units are shipped in bespoke crates designed to make shipping as cost effective as possible whilst ensuring safe delivery. Our crate supplier is a member of the UK Wood Packaging Material Marking Programme and is approved by the Forestry Commission to provide ISPM 15, which means their products are compliant with international standards, and are suitable for use worldwide.